Ultra-High Temp PFAS Destruction | HelioStorm™

Environmentally friendly & cost-effective PFAS destruction

Traditional Treatment Limitations

Conventional remediation strategies, including incineration, activated carbon filtration, and landfilling, have not delivered reliable results in eliminating PFAS. Many water treatment systems merely concentrate PFAS into spent filters, which themselves become hazardous waste. Meanwhile, incinerators often fail to reach the extremely high temperatures required to fully break the carbon-fluorine bond, leading to incomplete PFAS degradation or the formation of toxic byproducts. Landfilling PFAS-laden materials can lead to recontamination of groundwater and surrounding ecosystems, prolonging the risk and complicating regulatory compliance.

Why HelioStorm™ Is Different

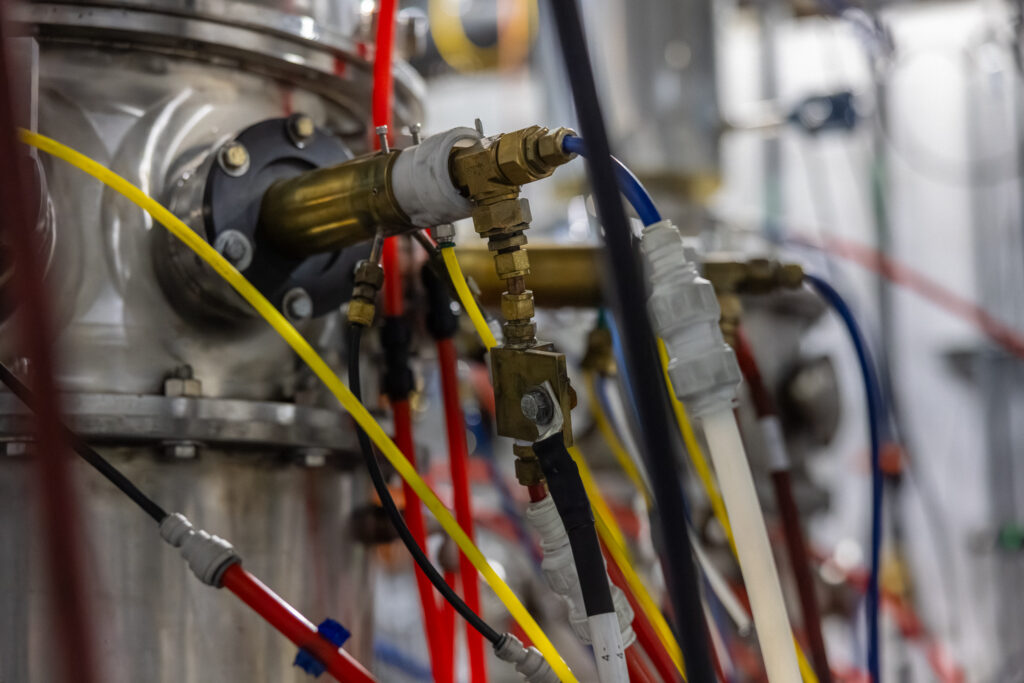

HelioStorm™ offers an entirely new approach to PFAS remediation. As a true PFAS destroyer, the system harnesses ultra-high plasma temperatures in a controlled, low-oxygen environment to enable destruction of PFAS compounds in biosolids. Unlike traditional thermal methods, HelioStorm™ doesn’t rely on combustion and avoids producing secondary contaminants.

Its core innovation lies in its ability to break even the toughest chemical bonds using ionic plasma reforming. The resulting byproducts—hydrogen (H₂) and carbon monoxide (CO)—are harnessed as clean syngas, which is used to generate electricity to power the system. This transforms what was once a liability into a renewable energy opportunity.

Key differentiators include:

- Complete thermal treatment with no reliance on combustion

- True PFAS destruction, not just containment or concentration

- Elimination of long-chain carbon residues

- Production of PFAS-free char and clean syngas

- On-site deployment, minimizing logistics and emissions

- Alignment with ESG goals and circular economy principles

By redefining how industries and municipalities address PFAS waste, HelioStorm™ provides a resilient, scalable, and sustainable tool in the fight against chemical pollution.

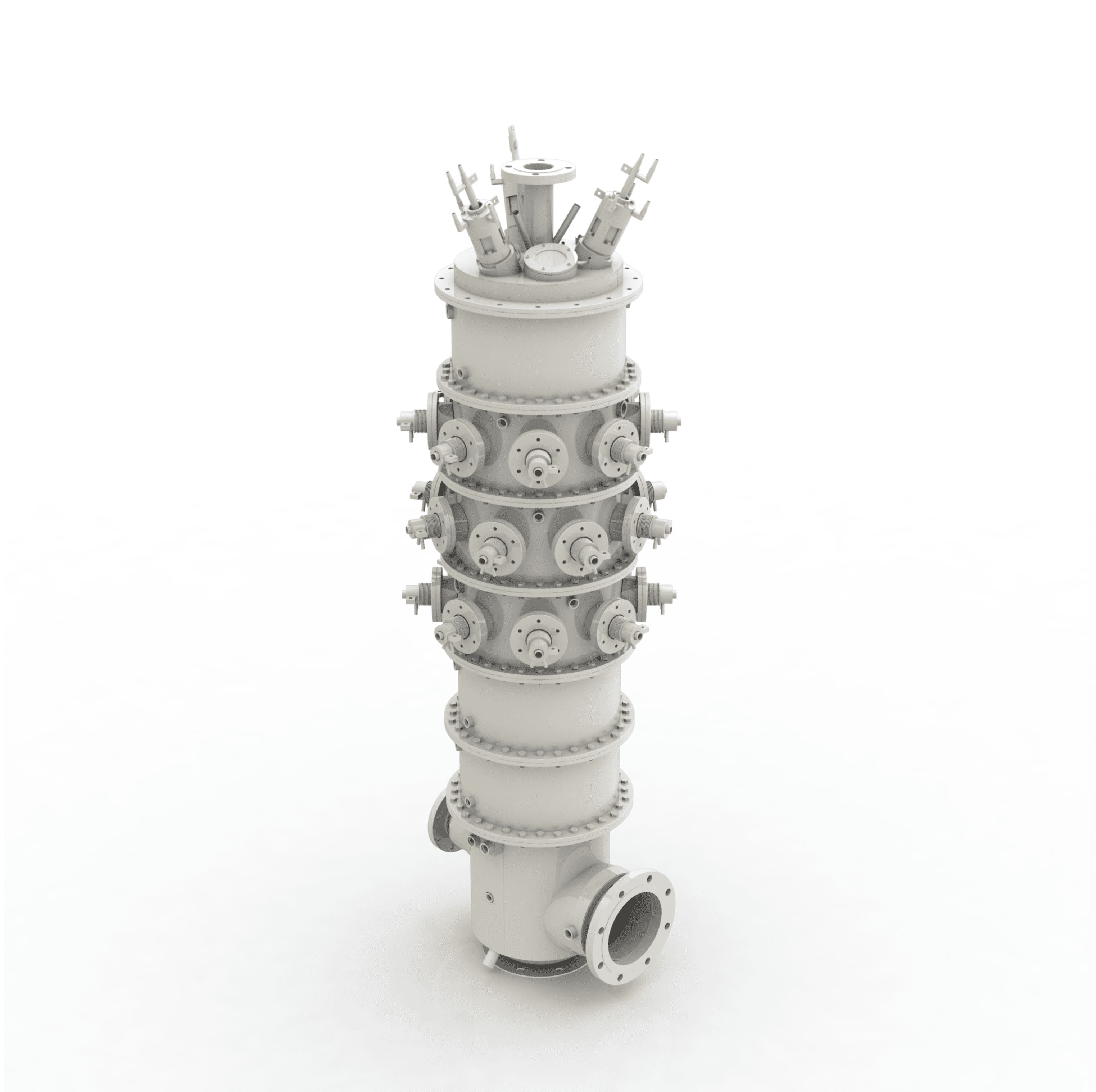

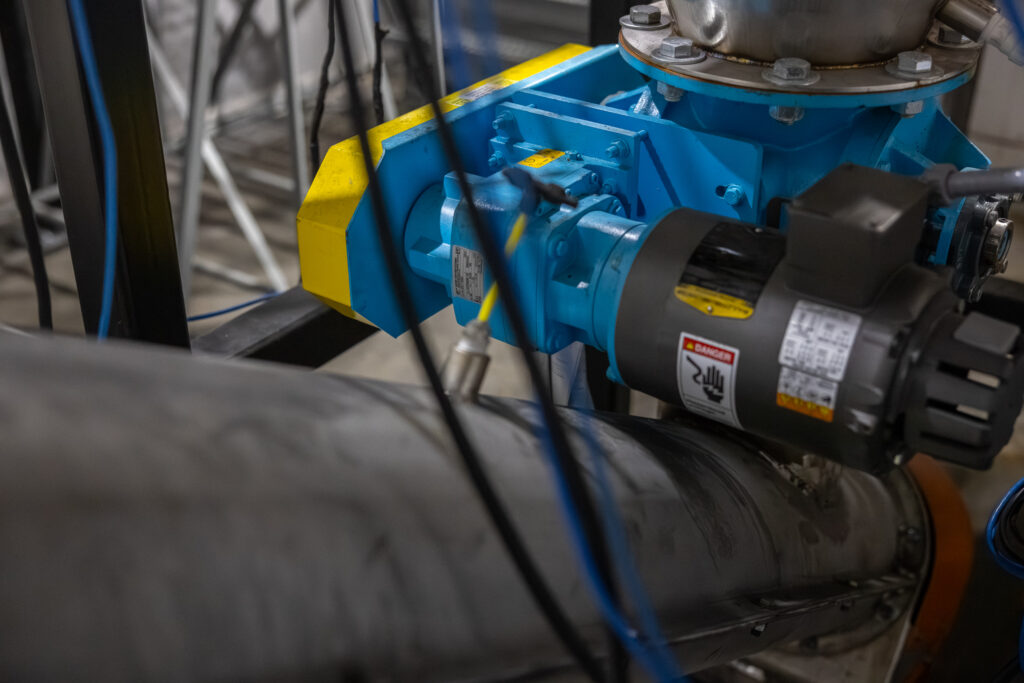

Plasma synthesis reformer (PSR)

How it works

-

Ultra-High TemperatureHelioStorm achieves temperatures between 3,000 and 10,000°C, maintaining an average temperature of 5,000°C across the reactor’s entire plasma field.

-

Assured PFAS DestructionDestroys PFAS compounds at reaction rates well above other thermal technologies.

-

Plasma SynthesisThe treatment and proceeding quench of feedstock compounds creates clean syngas, ideal for creating new molecules like low carbon fuels and chemicals.

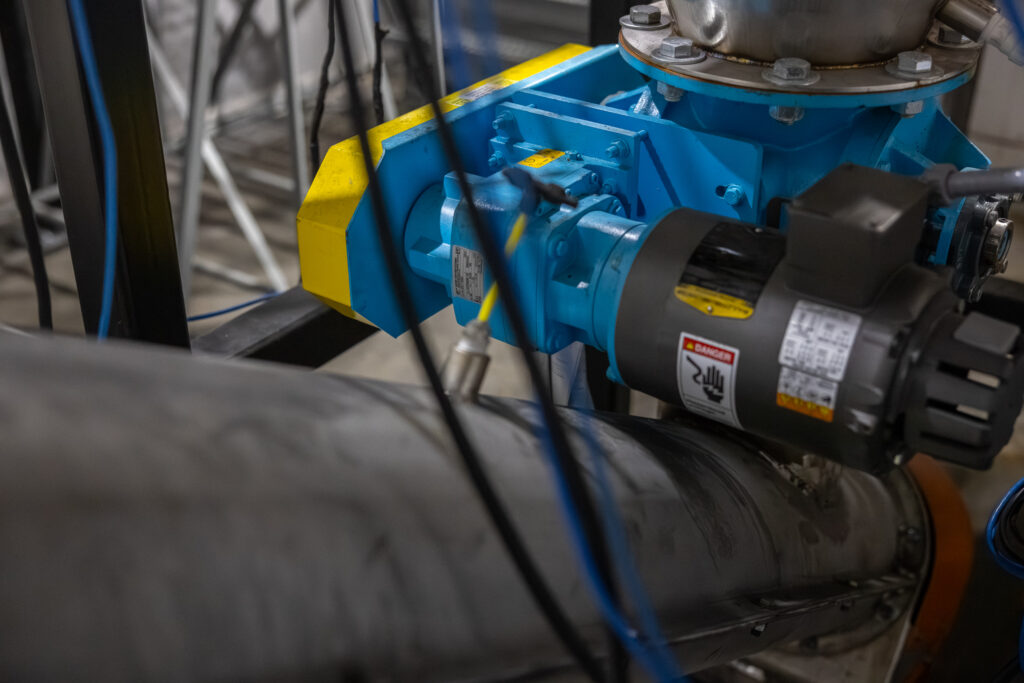

Built for Flexibility

The technology’s modular footprint and transportable design enable deployment at or near the point of waste generation. This supports:

- On-site waste stream management

- Reduced dependence on hauling or disposal contracts

- Localized energy production and lower greenhouse gas emissions

HelioStorm™ is redefining scalable PFAS remediation. It meets today’s growing demand for flexible, environmentally responsible, and economically viable waste solutions aligned with global sustainability mandates.

Whether your objective is PFAS degradation, compliance with regulation, or advancing your ESG goals, HelioStorm™ provides a proven platform for action.

Plasma Synthesis Reforming

A differentiated reformer

-

Tar freeprocess

-

thstate of matter

-

3000-10000°Coperating temperature

Environmentally friendly & cost-effective PFAS destruction

HelioStorm™ delivers measurable advantages across both sustainability and cost-saving dimensions. By providing an on-site, electrically driven PFAS destruction technology that does not rely on combustion, it avoids many of the costs and inefficiencies associated with traditional thermal treatment approaches.

- Clean Energy Generation: HelioStorm™ converts PFAS-contaminated waste into syngas—a mixture of hydrogen (H₂) and carbon monoxide (CO)—which is used to generate power for the system itself.

- Reduced Offsite Hauling: Because HelioStorm™ systems are modular and capable of on-site deployment, generators of PFAS waste no longer need to haul hazardous materials to remote incineration facilities or landfills. This dramatically reduces carbon emissions, operational costs, and liability risks.

- No Secondary Waste: Conventional water treatment and filtration systems often concentrate PFAS in spent filters or resin media, requiring separate hazardous waste disposal. HelioStorm™ achieves total PFAS degradation, eliminating the need for secondary containment or destruction.

- Lower Carbon Footprint: Electrically powered plasma synthesis produces minimal emissions, particularly when integrated with renewable energy sources. This enables facilities to meet carbon-neutral goals and improve their ESG reporting metrics.

- Regulatory Readiness: As governments move to enforce stricter PFAS regulation, HelioStorm™ provides forward-thinking organizations with a proactive solution. Its ability to meet future destruction standards positions clients ahead of evolving compliance frameworks.

In addition to these core benefits, HelioStorm™ contributes significantly to long-term strategic planning for sustainability and environmental risk management. It reduces reliance on legacy disposal infrastructure, which is increasingly costly and subject to growing regulatory scrutiny. The system also enables organizations to demonstrate leadership in environmental innovation, bolstering their reputation with stakeholders, investors, and the public.

The simplicity and reliability of HelioStorm™ operations reduce the need for extensive labor or oversight. With automated system monitoring and maintenance features, the technology can be deployed and scaled efficiently across multiple locations. This enhances waste management resilience for large organizations and governments.

For communities facing environmental justice challenges, the deployment of HelioStorm™ helps mitigate local exposure to PFAS contamination by removing the source of the hazard rather than relocating it. This ensures a higher standard of public health protection and environmental equity.

HelioStorm™ empowers businesses, municipalities, and industrial operators to implement PFAS remediation strategies that are sustainable, economical, and aligned with long-term climate and public health goals.

Application

The Heartland advantage

Choosing Heartland’s HelioStorm™ means partnering with a team that brings both cutting-edge technology and deep PFAS remediation expertise. As PFAS contamination becomes a critical issue for industries and municipalities, selecting a partner with a proven track record in PFAS destruction is essential.

Turnkey Solutions With Proven Results

Heartland stands apart as a turnkey PFAS destruction technology provider, overseeing every stage of project development—from feasibility assessment and permitting to installation, operation, and ongoing support. This hands-on approach ensures that clients benefit from a streamlined, efficient deployment process tailored to their unique site and regulatory needs.

Clients also gain access to Heartland’s unique Build-Own-Operate (BOO) model, which eliminates the need for upfront capital expenditures. This structure:

- Reduces financial risk

- Speeds up implementation

- Makes HelioStorm™ accessible to municipalities, industrial firms, and remediation specialists of all sizes

Distributed Deployment, Scalable Solutions

HelioStorm™ is engineered for decentralized, on-site waste processing. Its modular design allows clients to install units where PFAS waste is generated, minimizing the need for transportation and reducing emissions and liability. This model is ideal for:

- Water treatment plants

- Industrial and manufacturing facilities

- Remote environmental cleanup sites

It also aligns well with sustainability and operational resilience goals, providing an adaptable solution that evolves with changing waste management needs.

Demonstrated Success and Growing Demand

Heartland’s work spans sectors including wastewater treatment, military bases, chemical production, and environmental services. In pilot programs, HelioStorm™ has demonstrated:

- PFAS destruction rates exceeding 99.9%

- Significant reduction in hazardous waste and PFAS-contaminated materials

- Energy recovery in the form of usable syngas

- Measurable reductions in costs, waste liability, and carbon emissions

Partnering with Heartland means more than just accessing a powerful PFAS destroyer. It means aligning with a mission-driven company committed to environmental stewardship, operational excellence, and measurable outcomes.

From satisfying regulatory requirements to transforming waste streams into cleaner outputs, HelioStorm™ is more than a remediation tool. It’s a catalyst for progress.